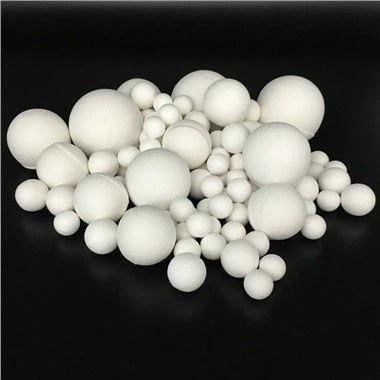

■ Description:

The aluminum content of high-alumina balls is 92% 95% 97%, and it is widely used in dry and wet grinding industries. According to the production process, it is divided into rolling balls and pressing balls. The product uses alumina ultrafine powder as the main raw material, which is fired by advanced molding technology and high temperature tunnel kiln. Widely used in petroleum, chemical and other industries as tower packing balls and catalyst carriers, for petrochemical plants, chemical fiber plants, alkylbenzene, ethylene plants, natural gas plants, etc. Demethylation devices, etc. are used as underfill materials.

■ Specific:

Shaping method |

AB92 |

Pressing Method |

φ30/40/50/60/70mm |

Rolling Method |

φ10-50mm |

Item |

AB92 |

Al2O3(%) |

≥92 |

ZrO2(%) |

0 |

Bulk Density(g/cm3 |

≥3.60 |

Water Absorption(%) |

<0.01 |

Abrasion Loss(‰) |

≤0.15 |

Mohs' Hardness |

9 |

Color |

White |

Remark: Regular size range from Dia.10 Dia.20 Dia.30 Dia.40 Dia.45 Dia.50 Dia.60 Dia.70.

Bigger size like Dia.80 Dia.90 Dia.100 are available upon requests

■ Packaging:

25kg net in PP-bag or big bag of 500 or 1000kg net. 20-24MT/20' FCL.

■ Key benefits:

● Extremely cost effective

● Improves grinding efficiency and energy costs

● Longer service time due to low wear rate

● Contamination-free to the color and composition of the ground material

■ Application:

Alumina grinding ceramic ball has been widely used in ball mills as abrasive media for ceramic raw materials and glaze materials in ceramic factories, cement factories, enamel factories and glasswork owing to the extraordinarily high density, high hardness and high wear resistance. During the abrasive grinding processes, ceramic balls will not be broken, and it will not contaminate the materials to be grinded.

It’s not affected by most chemicals, is non-conductive, non-magnetic, and chip-resistant.

In general ,inert alumina ceramic ball is not susceptible to chemical reactions, and its inherently dense texture, very low water absorption, does not act as a drying agent.

But they are widely used in petroleum, chemical, fertilizer, natural gas and environmental protection industries as a covering support material and tower packing for catalysts in the reactor.

Most of them are bottom-filling materials such as chemical fiber plant, alkylbenzene plant, aromatics plant and other hydrocracking refining equipment, catalytic reforming equipment, isomerization equipment, and demethylation equipment.

http://www.zbshell.com/

By certification

By certification